Bituminous binders

Traditional test equipment for bitumens and bitumen emulsions: needle penetrometer, ring and ball softening point apparatus, pH meter, electrical conductivity meter, laser diffraction particle size analyser, Engler and STV viscometers, drying balance for measuring emulsion water content, apparatus for measuring asphaltene content.

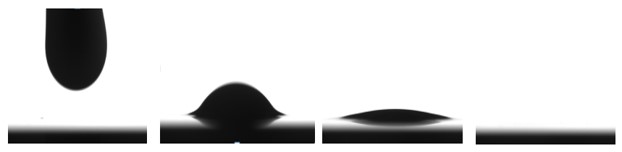

Methods for the physicochemical analysis of binders: Fourier- transform infrared spectroscopy, differential scanning calorimetry, thermoregulated goniometer for pendant and sessile drop analysis, simulated distillation, FID gas chromatography for the analysis of fumes, optical microscopy with a 3D stage under visible or UV light.

Rheological characterisation of binders: direct traction, ductility, bending beam rheometer, imposed stress and strain rheometers for measuring viscosity and complex modulus.

Specimen preparation facilities: mixer for manufacturing polymer-modified bitumen, colloidal mills for emulsions (1 and 5 litres), rotary evaporator distillation systems, centrifuge, oven.

Aging test facilities: Rolling Thin Film Oven Test, Pressure Aging Vessel, Enclosure equipped with UV rays and a rain cycle.

Facilities for producing bio-binders using a hydrothermal liquefaction process.