A circular economy using alternative and innovative binders

The production of transport infrastructure "consumes", large quantities of natural resources (aggregates, binders...), and energy. At the present time, the French Energy Transition Act (LTECV) urges us make construction materials more eco-friendly. In addition, infrastructure construction uses bituminous materials that are obtained from oil refining, such as bitumen, oils and synthetic polymers. This raises the issue of the inevitable reduction in oil supplies, whether deliberate or imposed, as well as the consequences of probable changes in oil refining strategies in the coming decades.

In this context, the main objectives of this theme are:

- to reduce bituminous mix manufacturing temperatures;

- to increase recycling rates for all materials;

- to perfect multi-recycling techniques for all materials;

- to develop new materials from biomass that provide alternatives to hydrocarbon binders, and apply biocalcification as an addition to hydraulic binders;

- to create hybrid solutions by mixing the above approaches (eg: 100% cold recycling in-situ using bio-sourced emulsion).

In these ways, the MIT lab is involved in developing new professional practices with greater use of so-called eco-efficient materials, using, for example, ever lower coating temperatures for bituminous materials (emulsion-based materials or warm mixes), or making increasing use of recycling (for bituminous, hydraulic and untreated materials), to move closer to the circular economy. It is also participating in the development of new viscoelastic binders derived from biomass – for example microalgae.

To do this, it draws on its mechanical, rheological and physicochemical expertise to assess the performance of these materials and their impact on the environment (energy consumption, pollutant and greenhouse gas emissions), to develop or improve mix design methods for the materials in question and to draw up recommendations for their use.

In recent years the laboratory’s important results in this area have included:

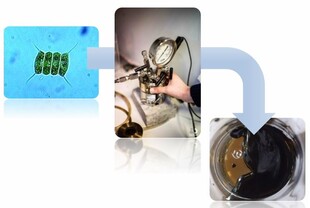

- a patent for a bitumen obtained from microalgae;

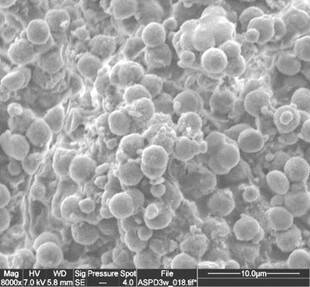

- initial results from the use of bacteria to improve recycled concrete aggregates;

- the use of Selenizza natural bitumen to formulate hard bitumens to slow down the oxidative aging of the organic matrix;

- the BioRePavation demonstrator which shows that using biobased binders or additives in recycling techniques can provide performance that is better than standard solutions;

- the development of in situ chemical tracers for monitoring the miscibility and aging of binders (ANR ImprovMURE);

- a 3D model of the behaviour of bitumen emulsion mixes (Cifre USIRF);

- an analytical protocol and recommendations for the evaluation of fumes from mixes and new tracers (ANSES project, Biorepavation);

- a patent for a cold storage method for bituminous mixes;

- a method for taking account of the performance of recycled concrete aggregates in the concrete design process (PN Recybéton);

- demonstration of the good mechanical response in the laboratory of warm materials incorporating multi-recycled materials (SUP & R ITN, PN Mure, ANR ImprovMure, RILEM);

Topics that are currently being explored include:

- the development of visco-elastic bio-binders sourced from microalgae or other biomass as an alternative to bitumen;

- the development of bio additives (bio-emulsifiers, fluxes, rejuvenators for recycling, bio-polymers, etc.) which reduce the impacts of bituminous mixes on health (fumes) and the environment (lower laying temperatures);

- control of the physical, physicochemical and mechanical parameters involved in the curing of bitumen emulsion mixes;

- the cold supply chain for bitumen;

- improving concrete recycling by the natural or biological carbonation of cement;

- bio-calcification as an alternative to conventional cement

Microalgae to bio-binders

Bio-calcification

bitumen - aggregate adhesion

Concrete recycling

Recycled aggregate